A Guide to Understanding Vertical Carousels

What is a Vertical Carousel?

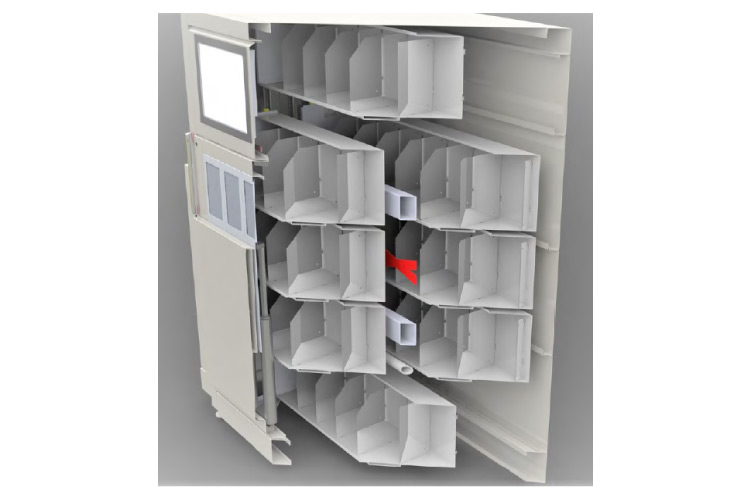

A vertical carousel is a high-density storage solution that operates on the vertical axis. The mechanism that drives a vertical carousel is similar to the mechanism that drives a Ferris wheel; however, rather than rotating on a circular path, as a Ferris wheel would, the shelving units move up and down vertically, following an elongated oval path.

This configuration means that vertical carousels can more than double the storage capacity of ordinary static shelving units.

In addition, vertical carousels can significantly improve warehouse performance. That’s because a vertical carousel’s internal mechanism is integrated with computer software, creating a true “goods-to-person” delivery system.

When a certain product needs to be picked, it is the software that directs the carousel to present the correct tote to the operator at the work counter. This accelerates pick speed, improves picking accuracy, and enhances workplace ergonomics.

Automated storage solutions offer many advantages vs. static shelving

Traditionally, most warehouse inventory has been stored on static shelving systems consisting of pullout drawers, wire racks, or pallet racking. Because the dimensions on static systems are fixed, they cannot optimize warehouse space.

Other more advanced storage solutions—whether they are vertical or horizontal carousels or vertical lift modules (VLMs)—can store items more densely than static shelving. These automated systems are all “goods-to-person” solutions because they utilize an operator based in a centralized location, and the goods move to the operator, rather than the operator moving to the goods.

Benefits of Vertical Carousel

Vertical carousels use automation to direct a pathway of standard shelves inside a single storage unit. Vertical carousels are ideal for storage of items in totes or of similar heights.

Vertical Carousel benefits include:

- Improved flexibility and efficiency in picking and fulfillment

- Fast ROI – companies can often recover their investment in less than 12 months

- Reduced labor – save up to two-thirds of previously required man-hours

- Optional totes, bins, and drawers for small and large components increase storage flexibility

- Easy integration – interface with WMS, ERP, and ERP systems

[Take it with you. Download the Guide to Understanding Vertical Carousels]

Vertical carousels offer a variety of business benefits

Vertical carousels offer numerous business benefits, ranging from increasing available floor space and maximizing storage density to accelerating pick speed, improving picking accuracy, and enhancing workplace ergonomics.

Vertical carousels can increase available floor space and maximize storage density

Vertical carousels are taller than they are wide. That means vertical carousels have a small footprint on the warehouse floor, freeing up valuable horizontal square footage for purposes other than storage. Put another way, vertical carousels optimize overhead air space, which is also known as “air rights.” Air rights tend to be the most underutilized space in factories and warehouses. Think about a typical warehouse, where the ceiling is 30-feet high. If that warehouse is using static shelving for storage, the shelving units are likely to be only 10-feet tall. That leaves about 20 feet of unused overhead space. Vertical carousels tap into that potential, increasing storage capacity without increasing the footprint on the warehouse floor.

Because they increase available floor space and maximize storage density, vertical carousels can be particularly useful in small spaces. For example, hospital pharmacies are about 2,000 square feet, on average. Not only do medications need to be stored in that space; pharmacists and technicians need to work there, too. SencorpWhite has been able to reduce the storage footprint in hospital pharmacies at least 50% by replacing static shelving with vertical carousels.

Vertical carousels accelerate pick speed

In warehouses that use vertical carousels, operators do not need to walk aisle by aisle to pick product. Instead, inventory is stored in the vertical carousel, and integrated computer software is used to call up product for delivery directly to the vertical carousel’s counter. This creates a true goods-to-person automated storage and delivery system. SencorpWhite vertical carousels also have a pick-to-light feature that lights up on the counter, identifying the product that’s supposed to be picked, the quantity needed, and the part, serial, or stock number. The operator can then pick the product and scan its bar code, verifying that they are picking the right product and the right quantity at the right time. This process significantly accelerates picking speeds. In fact, one of SencorpWhite’s pharmacy customers reduced pick times by 50% after installing our vertical carousel. (Note: The pick-to-light feature is also known as a put-to-light or tick bar.)

Vertical carousels improve picking accuracy and inventory control

SencorpWhite’s pick-to-light feature directs the operator to the tote they’re supposed to pick. It also identifies the correct bin within the tote and the required product amounts. This is all accomplished by technology that utilizes the data stored in the vertical carousel’s computer. Picking accuracy is critical, especially in hospital pharmacies. Let’s say a pharmacist needs to assemble a week’s worth of medications for a patient. Once the integrated software is programmed with which pills are needed for each day, the vertical carousel rotates and one by one, presents the right medication to the operator, with pick-to-light identifying the correct tote, bin, and quantity.

After the operator has completed a pick, the vertical carousel software can even automatically reduce the quantity of that product on hand in stock. SencorpWhite solutions use radiofrequency ID (RFID) tags that can be placed on each product inside the vertical carousel. These tags allow operators to verify every pick. They can also be used to track inventory, product expiration dates, and other inbound and outbound processes.

Vertical carousels offer ergonomic benefits

Vertical carousels eliminate the need for operators to bend or reach for items when picking. That’s because vertical carousels present product to operators at a counter that is 40 inches from the ground, the height recommended by agencies around the world as optimal for a work source. In addition, when vertical carousels are used, operators do not have to walk the warehouse floor or use a ladder or man lift machinery to access items stored on elevated shelves. Ergonomic benefits like these enhance employee satisfaction and lead to improved warehouse productivity.

Business benefits + SencorpWhite durability and reliability = Significant ROI

SencorpWhite vertical carousels are built to last, and we have many customers that are still using systems we built and installed more than 20 years ago. That durability and reliability combined with all of the benefits listed above creates significant ROI. In other words, averaged out over the vertical carousel’s lifetime, the cost of a SencorpWhite automated storage solution is minimal, compared to the savings possible due to improved warehouse performance.

[Take it with you. Download the Guide to Understanding Vertical Carousels]

How a vertical carousel system works

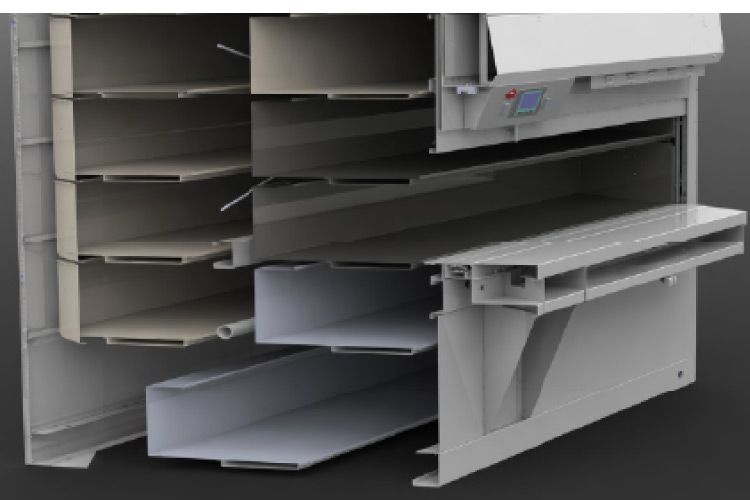

The mechanism that drives a vertical carousel is similar to the mechanism that drives a Ferris wheel. However, rather than rotating on a circular path, as a Ferris wheel would, the shelving units move up and down vertically, following an elongated oval path. The rotation is driven by a motor that spins a drive chain, which is attached to a torque tube extending across the interior of the carousel. This creates what is called a “drive side” and an “idle side.” But because the torque tube on the drive shaft is synced with the drive side, when the drive side spins, the idle side spins, generating the vertical motion up and around, over and over.

The internal mechanism of a vertical carousel is integrated with computer software, and when a certain product needs to be picked, it is the software that directs the carousel to the correct tote level. Within the vertical carousel, there is also a control box that receives the signal for a pick or a move. Once that signal is received, the motor spins the drive chain attached to the torque tube, and the vertical carousel turns to present the right shelf at the counter. At the same time, the pick-to-light feature on the counter identifies the product to be picked, the quantity needed, and the part, serial, or stock number. The operator can then pick the product and scan its bar code, verifying that they are picking the right product and the right quantity at the right time.

For SencorpWhite, safety is top priority

Years ago, the industry standard for vertical carousel safety was a light beam emitted from one side and received by a reflector on the other side (similar to how a garage door sensor works). However, today’s safety features for vertical carousels are much more advanced. SencorpWhite vertical carousels have a primary logistics controller (PLC) that continually checks the system to verify that every movement is safe. We utilize a light bar that scans the entire opening width from top to bottom and back and forth. If there is ever a break in that invisible plane of light, the machine comes to an immediate halt, preventing damage to person or product.

In addition to PLCs, SencorpWhite vertical carousels are equipped with overload and obstruction sensors. If there is too much weight, either vertically or horizontally, sensors recognize the overload and stop the vertical carousel from moving. Similarly, if product becomes loose or breaks off somewhere, sensors can recognize the obstruction, apply the brakes, and bring the machine comes to an immediate halt.

SencorpWhite vertical carousels are durable and reliable

SencorpWhite vertical carousels are built to last. For example, the New Orleans Hall of Records is still operating machines that we built in 1974. The key to this kind of longevity is preventative maintenance. Just as with a car or house, a vertical carousel will function best if it undergoes regular maintenance and occasional mechanical refreshes. SencorpWhite is the only vertical carousel manufacturer in North America with a dedicated in-house team of Field Service Engineers. This factory-trained service team is conveniently located throughout North America and provides the highest quality service available in the industry.

[Take it with you. Download the Guide to Understanding Vertical Carousels]

Vertical Carousels Can Be Customized To Meets Your Specific Needs

At SencorpWhite, we can customize our automated storage solutions to meet your specific business needs. That process begins with a thorough analysis of your stock listing. Once we fully understand the type, quantities, and weight of the products you need to store, we can begin to design a solution that will work best for you. We have designed and built systems that can store and retrieve small, lightweight items like jewelry and fasteners or large, heavyweight items like iron pipe and airplane parts—and everything in between.

Using multiple vertical carousels for batch picking to increase productivity

In certain cases, multiple vertical carousels are required. For example, if there is too much product to fit in one vertical carousel, another is needed. Alternatively, warehouse managers may need multiple vertical carousels because they want to implement batch picking. With batch picking, orders with the same pick requirements are grouped together into small batches. That way, the operator can pick product for all of one batch at the same time. When multiple vertical carousels are used for batch picking, different batch picks can be run simultaneously, increasing speed and efficiency.

Vertical carousels for clean room environments

SencorpWhite offers automated storage and retrieval systems for distribution and point-of-use inventory management of high-value medical devices, instruments, implantables, and pharmaceuticals that must remain sterile. For instance, hospital pharmacies must use clean room environments for compounding certain medications. Our dual-sided vertical carousels for clean rooms enable operators to access products from either sterile or non-sterile environments. That way, operators on the sterile side do not need to leave the clean room to access components. Remember, every time someone leaves a clean room, they need to take off their personal protective equipment (PPE), and every time someone enters a clean room, they need to put on fresh PPE. With our dual-sided vertical carousels for clean rooms, operators can do their jobs without having to leave the sterile environment. They can work more easily and efficiently—and PPE costs are significantly reduced.

Vertical carousels for products that must be stored at certain temperatures

Certain products must be stored in temperature-regulated conditions. For example, many new pharmaceuticals must be refrigerated to ensure and preserve efficacy. Likewise, grocers offering curbside pick-up need to store orders at three different temperatures: ambient, refrigerated, and frozen. In other instances, storage must be at higher-than-ambient temperatures (to ensure that a product cures properly, e.g.). SencorpWhite makes vertical carousels that provide dynamic temperature-regulated storage for whatever conditions are required. In addition to providing temperature-regulated storage, these units free up valuable floor space. For instance, one vertical carousel can have the storage capacity of multiple refrigerators—and with a much smaller footprint. What’s more, because of their integration with computer software, these systems can improve inventory control and management.

Finding the right vertical carousel for your business

SencorpWhite vertical carousels can be customized with a variety of options. First, we will work with you to determine what size your system should be and how many levels of storage are optimal. Our vertical carousels can be built with pans that range in size from tall and long to short and deep. The size and shape of the pans impacts the total number of possible shelves. Beyond that, we also offer customization with regard to color, barcode readers, infrared scanners, and RFID tags. We can even build vertical carousels with specialized features for fire suppression, Halon, or CO2 spray. At SencorpWhite, we consider the design and build of vertical carousels to be a collaborative process.

[Take it with you. Download the Guide to Understanding Vertical Carousels]

Steps In The Installation Process Of A Vertical Carousel

At SencorpWhite, we build the sub-assemblies for our vertical carousels in our factory in Hyannis, MA. Usually, these are shipped to customers in 53-foot tractor trailer trucks. Then, our installers meet the truck at the customer’s loading dock, remove the components, and finish the assembly on-site. The assembly typically requires a day and after that, another day is needed to complete the installation, debug, and make certain the system is running perfectly.

Regular maintenance leads to optimal performance

A SencorpWhite maintenance contract will help ensure you receive the maximum ROI from your vertical carousel. Typically, there are two preventative maintenance visits per year, when our technician spends a couple hours evaluating the system, inspecting the wiring, tracks, wheels, and other internal components. They also observe the machine in motion, lubricate the chain tracks, chains, and drive chain, and complete any necessary repairs. Some of our customers use their vertical carousels 24 hours a day, seven days a week; others may use them somewhat less frequently. Either way, regular maintenance and occasional mechanical refreshes are vital for optimal performance.

[Take it with you. Download the Guide to Understanding Vertical Carousels]

Calculating The Return On Investment Of A Vertical Carousel

Vertical carousels offer numerous business benefits, ranging from increasing available floor space and maximizing storage density to accelerating pick speed, improving picking accuracy, and enhancing workplace ergonomics.

For some of our customers, adding a vertical carousel meant increasing storage capacity by 50-60% and eliminating the need to add (or move to) another warehouse.

For others, the biggest benefits have been in labor reductions enabled by increased warehouse performance or from savings realized through improved shipping accuracy. When a factory, warehouse, or pharmacy starts using a vertical carousel that’s been customized for them, the business benefits can typically be calculated in multiple ways, all of which lead to significant ROI.

[Take it with you. Download the Guide to Understanding Vertical Carousels]

Take it With You

Download the Guide in pdf format.