Aerospace Vertical Lift Modules (VLMs)

Optimized Storage for High-Value, Mission-Critical Components

In the aerospace industry, space is at a premium—and so is precision. White Systems’ Vertical Lift Modules (VLMs) are transforming how aerospace manufacturers, MRO facilities, and defense contractors store and retrieve high-value components, tools, and parts. By utilizing vertical space, VLMs dramatically reduce floor space requirements while increasing storage capacity. Designed for demanding environments, VLMs provide secure, ergonomic, and efficient access to mission-critical inventory, improving accuracy, traceability, and throughput.

See how a Vertical Lift Module (VLM) works from the inside out.

Why Aerospace Facilities Choose VLMs

-

Space Optimization: Store up to 85% more inventory in the same footprint by utilizing vertical space—ideal for cramped hangars or cleanroom environments.

-

Inventory Accuracy: Achieve up to 99% inventory accuracy with real-time tracking and integration to WMS systems, reducing costly stockouts and mispicks.

-

Improved Ergonomics: Operators retrieve parts at waist height, reducing strain and injury while speeding up operations.

- Optimized MRO Operations: Speed up maintenance workflows by staging frequently used parts at ergonomic access points.

- Customizable for Aerospace Applications: Tailored tray sizes, and outdoor-rated configurations.

-

High Security: Limit access to sensitive or ITAR-controlled components with tiered user permissions and audit trails.

-

Cleanroom & ESD Options: VLMs can be customized for clean environments and electrostatic-sensitive devices.

-

U.S.-Based Service Team with Aerospace Experience: Rapid response from techs who understand regulated environments and critical uptime needs.

How One MRO Team Transformed F-35 Maintenance with VLMs

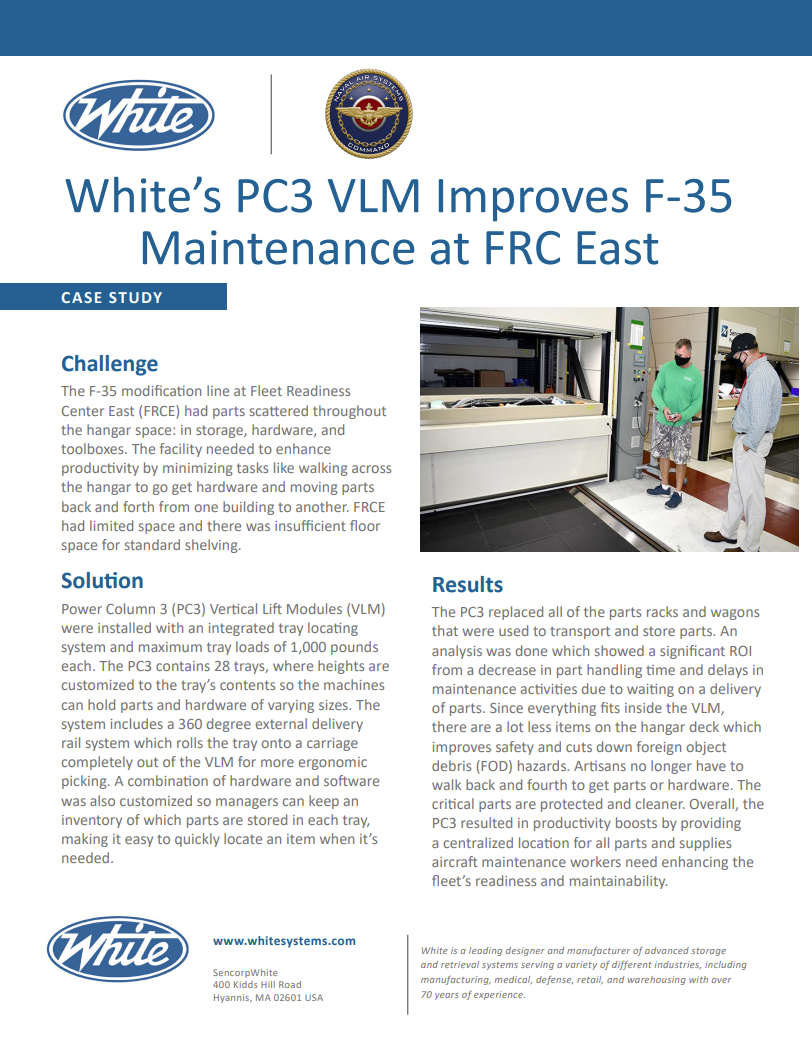

Fleet Readiness Center East needed to streamline F-35 part storage and eliminate clutter across the hangar. By installing White’s PC3 VLMs, they improved speed, accuracy, and safety—directly boosting fleet readiness.

Key Results:

- Saved Space: Replaced racks with 28 high-capacity trays tailored to part sizes.

- Improved Safety & Access: 360° tray delivery reduced strain and FOD risks.

- Faster Retrieval: Custom software enabled quick, accurate part location.

A technician demonstrates the operation of a Vertical Lift Module (VLM).

White Systems' Flexible Solutions for Aerospace Operations

PowerColumn3 (PC3)

Engineered and made in the USA, the PC3 holds up to 2,000 lbs per tray and stores large, bulky items with ease. It can be customized for indoor or outdoor installation, tray sizes, access height, and more.

Compact Double VLM

Maximize density with 4 trays per level and the most efficient footprint in our VLM line. Ideal for retail operations needing extreme storage capacity and optimized picking in a tight space.

Built for Aerospace. Backed by ROI.

White’s VLMs deliver the precision and space efficiency aerospace operations demand—see the numbers for yourself.