Automated vertical storage systems such as vertical lift modules (VLMs), vertical carousels and horizontal carousels are designed to run around the clock. When these machines go down, every minute of unplanned downtime adds stress and costs to your operation. A robust automated storage service program—one that combines proactive maintenance, fast on‑site support and a comprehensive spare‑parts program—is just as important as the equipment itself.

In this blog post we’ll step back from the nuts and bolts of our products and explore why service contracts matter for businesses that rely on AS/RS technology. Whether you’re comparing service packages, trying to understand industry best practices or simply curious about what to look for in a provider, this article will give you the context you need to make an informed decision. We’ll break down the main components of a contract, look at who benefits from each level of coverage, and share tips drawn from years of supporting warehouses, manufacturers and hospitals.

Why an Automated Storage Service Contract Matters

For warehouses, production plants and hospitals relying on automated storage and retrieval systems (AS/RS), a machine stoppage can ripple through the entire operation. The impacts include:

-

Delays in order fulfillment: When inventory is inaccessible, picking and kitting tasks grind to a halt.

-

Lost productivity: Operators and material handlers lose valuable time waiting for service technicians or searching for parts.

-

Safety risks: Work‑arounds—like manual picks from high shelves—expose employees to ergonomic hazards and potential accidents.

-

Reduced return on investment: Every hour of unplanned downtime delays the ROI that businesses expect from automation.

Minimizing downtime therefore isn’t just about fixing equipment quickly; it requires a holistic support strategy that prevents issues before they happen and makes recoveries swift when they do.

Why U.S.‑Based and Local Service Matters

When your operation relies on automated storage equipment, having a service partner who is geographically close and understands your environment makes a measurable difference. Companies that assign technicians based near their customers can respond faster when issues arise and bring a deeper familiarity with the machines they support. This proximity reduces travel time and ensures that maintenance visits and emergency calls are more efficient and cost‑effective.

The most effective service programs are built on three pillars:

- Preventative Maintenance: Service agreements should include scheduled maintenance tailored to each machine’s needs. Technicians follow detailed checklists and provide documentation that helps reduce downtime and extend equipment life. Regular inspections catch wear‑and‑tear before it escalates into a failure.

- Fast, Expert On‑Site Support: If something goes wrong, help should arrive quickly. Providers who strive to be on site by the next business day—or within a set window for premium contracts—can diagnose and repair issues efficiently because they bring the right parts and deep product knowledge.

- Predictable, Cost‑Effective Coverage: Service contract holders benefit from discounted labor rates and guaranteed pricing—even when visits run long or involve travel delays. Clear terms give operations teams the ability to budget accurately and avoid surprise invoices.

How to Evaluate Automated Storage Service Contracts

Choosing a contract isn’t just about comparing price tags—it’s about understanding what’s included and how it aligns with your business priorities. Here are a few factors to weigh when assessing an automated storage service contract:

-

Response time commitments: Look for clearly stated targets for how quickly technicians will be on site. Some providers promise next‑business‑day visits, while premium packages may offer 24‑hour or even same‑day response.

-

Maintenance frequency and scope: Ask how often preventative maintenance is performed and what is covered. A good contract will define inspection intervals, parts replacement schedules and reporting procedures.

-

Parts availability: Find out whether the provider stocks critical spare parts locally or regionally and whether you can keep parts on site. Ready access to components speeds repairs and prevents extended downtime.

-

Support channels: Understand how to reach the service team—by phone, email or online—and during which hours. Make sure the coverage aligns with your operating schedule.

-

Cost structure: Clarify what is included in your monthly or annual fee and what costs extra (such as parts or after‑hours labor). Predictable pricing helps avoid surprises when you need service the most.

Explore White Systems’ Service Contract Options: Silver vs. Gold

White Systems offers two service levels to match different operational needs. The Silver plan provides business-hours coverage, including preventative maintenance, standard phone and email support, and a dedicated Field Service Engineer. For facilities that require higher uptime, the Gold plan adds 24/7/365 support, faster response times, and priority scheduling for critical operations.

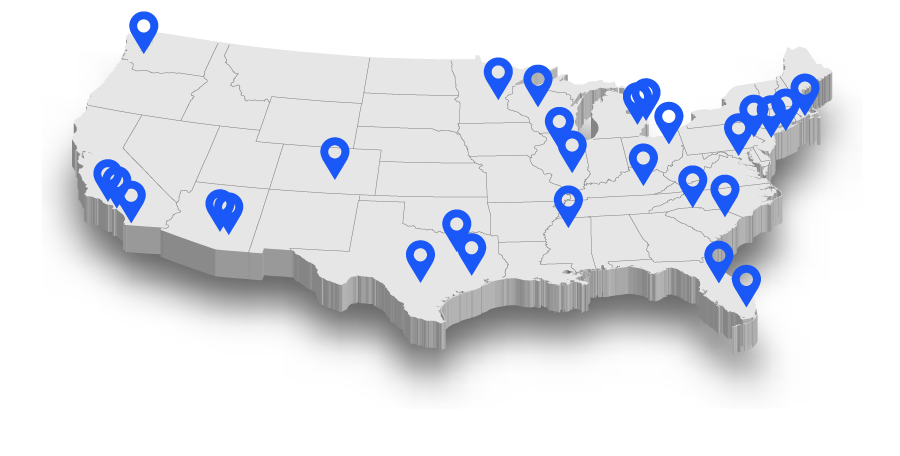

Nationwide Coverage

White Systems maintains a network of factory‑trained field service engineers across the United States. FSEs are strategically located for faster response times, ensuring that help is nearby when you need it. Because every technician is a White Systems employee, there’s no learning curve when they arrive on site.

Benefits of Proactive Service Contracts

Investing in a service contract goes beyond reacting to problems. Here’s how proactive support translates into tangible benefits:

-

Reduced downtime: Scheduled maintenance catches issues early, while priority response ensures that any unexpected failures are resolved quickly.

-

Extended equipment life: Regular inspections and timely parts replacement prevent small problems from causing major damage, extending the life of your VLMs and carousels.

-

Better safety and compliance: Keeping equipment in top condition helps operators avoid unsafe work‑arounds and ensures compliance with OSHA and other standards.

-

Budget predictability: Fixed labor rates and guaranteed pricing enable accurate budgeting and reduce financial surprises.

-

Peace of mind: Knowing that a dedicated FSE is just a phone call away lets your team focus on core activities rather than troubleshooting machinery.

Minimizing downtime in automated storage is not a one‑time project—it’s an ongoing commitment. White Systems’ service contracts integrate scheduled maintenance, fast on‑site response and robust service support to keep your VLMs and carousels running at peak efficiency.

Ready to learn more about protecting your automated storage system? Contact our service team at 508‑771‑9400 or email service@sencorpwhite.com to discuss how a tailored service plan can keep your operation running smoothly.