Defense & Federal Logistics Vertical Lift Modules (VLMs) & Carousels

Secure vertical storage for defense & federal logistics operations

Defense and federal logistics teams require controlled access, reliable uptime, and consistent inventory handling for mission-critical parts and tools. White Systems’ Vertical Lift Modules (VLMs) provide secure, space-efficient storage that supports accountability, safety, and operational readiness in maintenance, depot, and supply environments.

White Systems supports both government-operated facilities and prime contractors & system integrators delivering storage solutions into defense and federal environments.

Designed for MRO, depot maintenance, and logistics facilities supporting DoD and DLA operations.

See how a VLM delivers controlled access, faster retrieval, and a complete transaction history.

Who this solution is built for

Government & federal operations

Ideal for:

-

DoD & DLA depots

-

Fleet readiness centers

-

Base-level maintenance

-

Federal logistics facilities

What matters most:

-

Controlled access & accountability

-

Audit-ready transaction history

-

Standardized, repeatable workflows

-

Long-term serviceability & uptime

Prime contractors & integrators

Ideal for:

-

Defense primes

-

MRO contractors

-

Systems integrators

-

Facility modernization programs

What matters most:

-

Proven deployments in regulated environments

-

Configurable systems that meet spec

-

Support through install, approval, and sustainment

-

U.S.-based service and long-term lifecycle support

Why defense & federal facilities use VLMs

Supported by U.S.-based technicians and long-term government programs.

-

Secure, Heavy-Duty Storage

Industrial rack-and-pinion design with tray capacities up to 2,000 lbs—built for mission-critical parts. -

Controlled Access & Usage Records

Role-based access and transaction history support accountability and traceability. -

Software-Managed Inventory & Traceability

Software-directed transactions provide real-time visibility and a complete audit trail. -

Space Optimization in Constrained Facilities

Vertical storage reclaims up to 85% of floor space in hangars, depots, and legacy buildings. -

Faster, More Consistent Retrieval

Goods-to-person delivery reduces search time and variability. -

Optimized MRO Workflows

Frequently used parts are delivered at ergonomic access points. -

Ergonomic & Safe Operation

Controlled tray delivery and safety features support FOD reduction. -

Configurable for Government Environments

Flexible tray layouts, ESD options, and environmental configurations. -

U.S.-Based Service & Long-Term Support

Nationwide field service with contract support options.

Why defense & federal teams choose White Systems

-

Proven in regulated environments

Deployed in defense depots, flight-line maintenance, and secure logistics facilities. -

Designed for accountability and uptime

Controlled access, transaction history, and industrial reliability support mission readiness. -

U.S.-based service and long-term support

Directly employed technicians and contract support for sustained operations. -

Configurable for government requirements

Heavy-duty storage, ESD options, environmental configurations, and secure layouts.

Configured for defense, depot, and federal logistics environments

PowerColumn3 (PC3)

Engineered and made in the USA, the PC3 holds up to 2,000 lbs per tray and stores large, bulky items with ease. It can be customized for indoor or outdoor installation, tray sizes, access height, and more. Commonly deployed for heavy MRO, tooling, and aviation ground support inventory in secure facilities.

Compact Double VLM

Maximize density with 4 trays per level and the most efficient footprint in our VLM line. Ideal for high-density parts storage in constrained government facilities.

Case study: Faster, safer parts access for flight-line maintenance

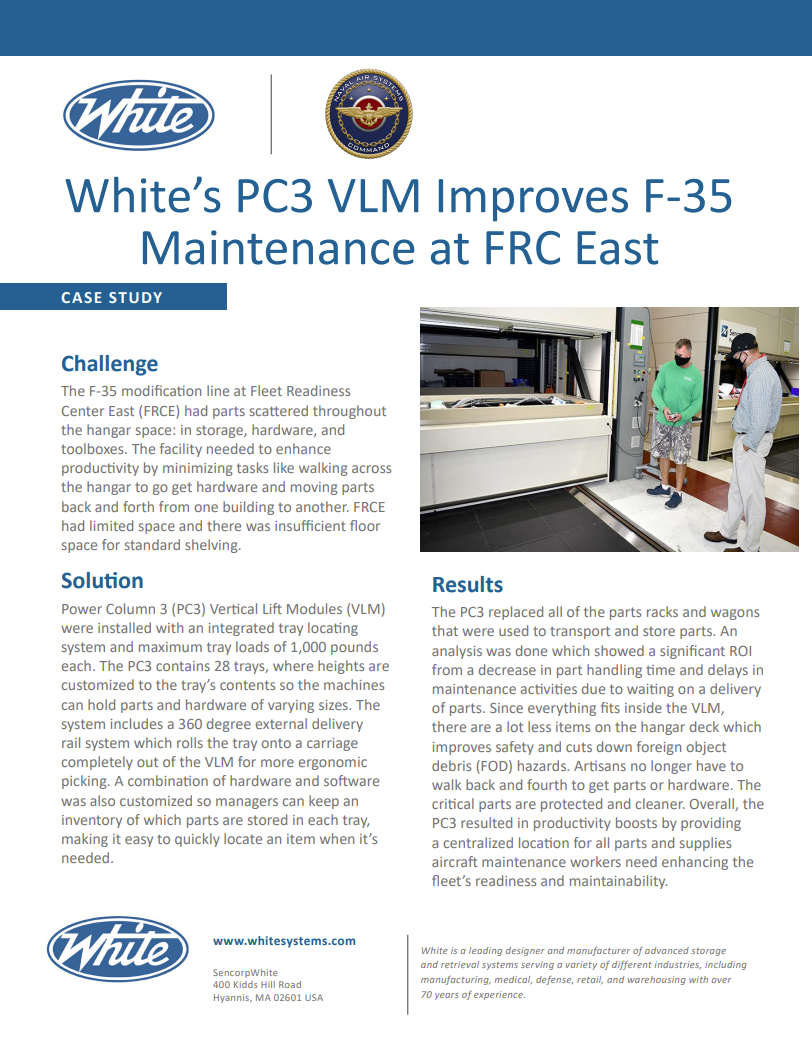

Fleet Readiness Center East streamlined F-35 parts storage and reduced hangar clutter by installing White PC3 VLMs. The result was faster retrieval, better organization, and improved control of maintenance inventory to support fleet readiness.

A technician demonstrates the operation of a Vertical Lift Module (VLM).

Key Results:

- Saved Space: Replaced racks with 28 high-capacity trays tailored to part sizes.

- Improved Safety & Access: 360° tray delivery reduced strain and FOD risks.

- Faster Retrieval: Software-directed workflows enabled quick, accurate part location.

-

How much could you save with smarter storage?

White’s Vertical Lift Modules are engineered to meet strict government standards—now See how standardized vertical storage can reduce space constraints, improve inventory control, and support long-term facility planning. Our quick ROI calculator shows the potential impact on your budget, labor, and storage capacity.