When considering the investment in a Vertical Lift Module (VLM), warehouse managers need to weigh several factors, including cost, size, and the potential return on investment. These systems provide a significant boost in picking performance and operational efficiency, making them a valuable asset for modern warehouses.

However, understanding the price range and the variables that influence this cost is crucial. This guide will explore the determinants of VLM pricing, the benefits of leasing versus buying, and how to calculate the ROI, helping you make an informed decision tailored to your warehouse’s needs.

Factors Influencing the Cost of Vertical Lift Modules

Customized Dimension Specifications

The dimensions of a Vertical Lift Module (VLM) play a significant role in determining its cost, as they directly influence the materials needed, manufacturing complexity, and installation requirements. Larger VLMs, designed to accommodate more inventory or heavier loads, require more robust construction, which increases the cost of materials and engineering. Additionally, customized dimensions to fit specific warehouse layouts or ceiling heights can add to the complexity of the design, often leading to higher costs.

Depending on your specific requirements for Vertical Lift Modules (VLMs) are primarily sized based on tray width, with common sizes ranging from 3 feet to 20 feet. The most popular tray widths are 96 inches, 120 inches, and 144 inches. While the width of the system is determined by the tray size, the overall machine is slightly larger to accommodate the tray’s movement as it slides in and out to present items.

It is also important to consider the weight capacity when designing your customized vertical lift module so that you can safety store and retrieve your inventory. The weight capacity for each system ranges by size and tray capacities. The standard/high-speed models can hold 50 tons while the specialty heavy-double can store 100 tons. The trays have a max load of 660 or 1100 lbs, but trays can always be customized for higher capacities.

The vertical lift systems come in various heights, typically designed to match the warehouse ceiling, with standard heights being 18 feet, 27 feet, and 36 feet. The depth of a VLM is influenced by the tray depth, which generally measures 32 inches. The total depth of a VLM is the sum of the tray depth and the space needed for the elevator between the trays. For example, a VLM with two trays usually has a total depth of around 10 feet. However, custom manufacturing can provide narrower trays and overall depths if needed.

To further explore the available dimensions, reference our configurator to build your own VLM.

Specifically Designed Features

When determining the cost of a Vertical Lift Module (VLM), it’s essential to consider the specific benefits you are willing to invest in to achieve a rapid return on investment (ROI). All of our VLMs include user-friendly interfaces with computerized control systems, LED bar guidance, safety curtains, and an elevator delivery system, among other features. Our four types of VLMs each offer unique features and functional benefits tailored to different needs.

Trays have the option to be weighed and organized each time they enter or exit the module, with an accuracy of 5-10%. For those requiring higher precision, advanced weighing technology is available as an optional upgrade. When it comes to the integrated software costs, there is a significant variance ranging from $500 to over $100,000, depending on the complexity and features required. Additionally, various accessories such as printers, barcode scanners, pick-to-light systems, laser pointers, and LED bars can be integrated, typically costing around $1,000 each.

Average Cost Ranges

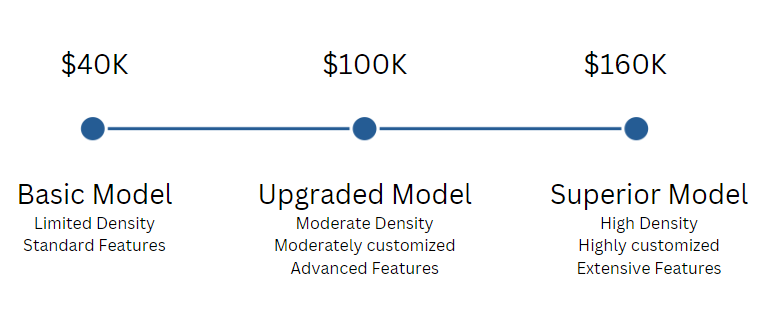

Keeping in mind that the cost of a vertical lift module varies depending on the specified design features, size, and customizations, here is an overview of some average costs.

Average Cost Based on Model Types

There are three main types of vertical lift modules (VLMs): single lift, twin lift, and double lift. The cost of each different type of VLM is determined by size, weight, capabilities, and options.

- Our Compact Vertical Lift Module typically costs $40,000+, varying depending on size, weight, and features; it lifts one tray at a time.

- Our Compact Twin Vertical Lift Module usually costs $5000-$7000 more than single lift VLM, due to a higher-powered propulsion system and elevator which can carry two trays at once. This boosts picking speeds, as a second tray can be sent to an operator while they are still picking from the first.

- The Compact Double Vertical Lift Module, an adaptation of the twin lift, can hold four trays per layer. It’s slightly slower since it picks up two trays at a time, but has double the storage. This makes it the most budget-friendly option.

Commonly Asked Questions

What are the different ways to express the cost of a VLM?

A VLM’s price can be calculated in several ways. For example, using storage capacity to divide the cost per square foot, meter, or kilo. It is common to measure cost by number of picks or presentations it allows. As labor costs rise, picks per hour are the best way to measure cost and value. In Europe, the main factor is the cost of conventional storage per stored unit versus the same amount stored in a VLM.

What costs should be included when calculating the ROI for a VLM?

Calculate ROI of VLM by accounting for acquisition, installation, shipping, operation, maintenance costs & training (if applicable).

What are the typical maintenance and maintenance costs associated with a virtual lift module?

VLM maintenance usually focuses on the drive system. Belts must be serviced/replaced at intervals. Chain drives need inspection, lubrication, and adjustment, but can last the entire life of the machine. Rack and pinions require little service, but should be checked and lubed yearly. On some models, drive wheels may need to be replaced after a while.

What is the average picking speed difference between a single lift and a Twin Turbo VLM?

A typical VLM takes 45-60 seconds for batch-picking. Our Twin Turbo VLM offers 30-40% more trays per hour than a single lift VLM.

What are the different types of specialty vertical lift modules?

We build heavy-duty VLMs, with a tray capacity up to 3000lbs and capable of holding 220,000lbs. These are suitable for storing heavy components such as tools, dies, molds and motors. Wide units of over 12 feet are available to store long items such as pipe and extrusions.