Maximize Uptime and Inventory Control with Smart Storage for Manufacturing & MRO

Maximize Uptime and Inventory Control with Smart Storage for Manufacturing & MRO

Store critical parts and tools in one place for faster access and safer operations.

Store critical parts and tools in one place for faster access and safer operations.

Our Vertical Lift Modules help maintenance and production teams stay organized, minimize downtime, and reclaim up to 85% of floor space—all with 99% pick accuracy and expert U.S.-based service.

“The PC3 helped us eliminate parts racks and manual transport completely. Now everything is in one place protected, organized, and easy to access. It’s boosted productivity and given us full control over our parts inventory.”

— Maintenance Lead, FRC East

Ready to Optimize Your Storage?

Ready to Optimize Your Storage?

Let’s talk about how you can streamline storage for tools, spares, and supplies.

Storage Benefits for Manufacturing & MRO Teams

Maximize Floor Space

Save up to 85% of floor space

Reduce Downtime

Streamlines access to parts

Enhance Ergonomics & Safety

Trays delivered at optimal height

Improve Inventory Accuracy

Picking improved by up to 99%

Secure Critical Items

Restrict access based on user roles

Why MRO Teams Choose White Systems

- U.S.-Based Support: Fast response from techs who understand manufacturing

- Built for Industry: Designed for tough, high-use environments

- Tailored Configurations: Fits your space, inventory, and workflow

- High-Density Storage: Store more tools, spares, and consumables

- Secure Access: Limit access to critical or regulated items

-

Features of Our Automated Storage Systems

-

Dual tray levels for compact, high-density storage

-

Rack & pinion drive for speed and reliability

-

Up to 40′ tall units, ideal for manufacturing floors

-

ERP & WMS integration

-

LED bar for guided picking

Expert Service & Support

Every vertical lift module comes backed by our U.S.-based service team, with factory-trained Field Service Engineers located across the U.S. We keep your system running smoothly with preventative maintenance and fast on-site support, so you can stay focused on what matters most.

See how our VLM is ideal for high-throughput MRO and manufacturing environments

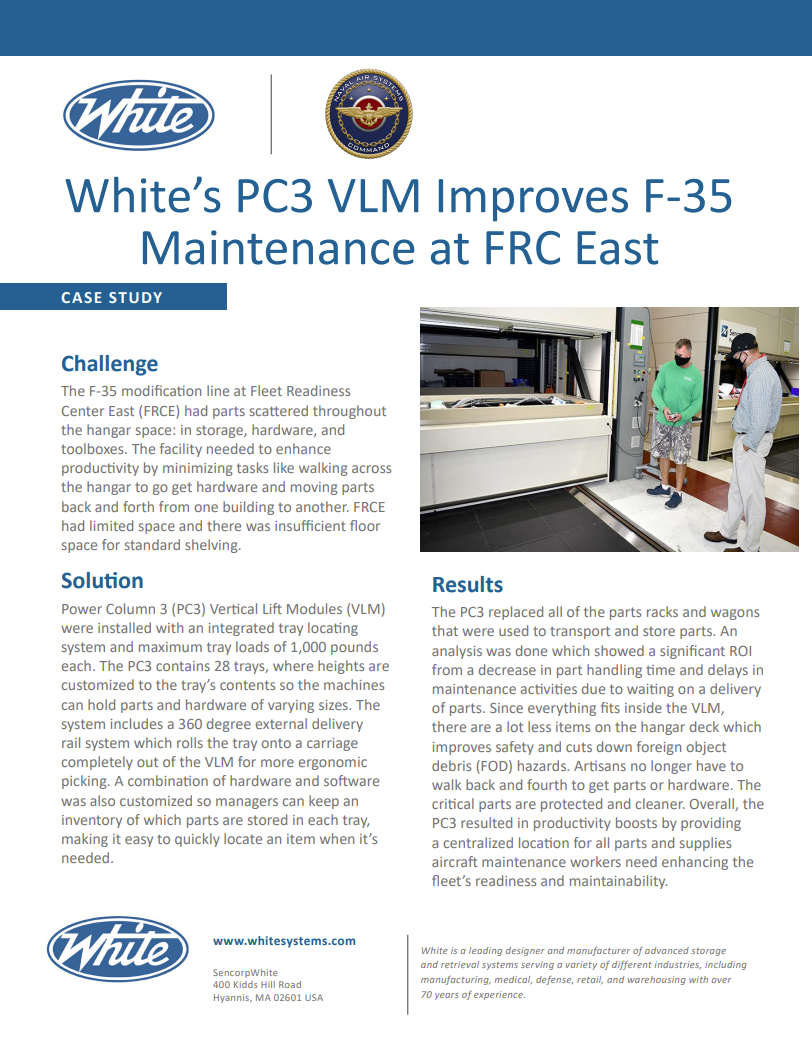

Case Study: Boosting F-35 Maintenance at FRC East

The maintenance team at Fleet Readiness Center East (FRCE) faced cluttered hangars, scattered inventory, and lost time walking between buildings to retrieve parts.

Solution:

White’s Power Column 3 (PC3) Vertical Lift Modules centralized storage and replaced racks, toolboxes, and transport wagons. With 28 heavy-duty trays and integrated inventory tracking, the PC3 streamlined access to mission-critical parts.

Results:

-

Faster access to parts with less walking and searching

-

Reduced delays in maintenance activities

-

Improved safety by clearing the hangar floor

-

Better protection and cleanliness for high-value items

Ready to Solve Your Inventory Challenges?

Connect with our team to explore how vertical storage can support your production uptime, streamline MRO operations, and boost overall efficiency.