Automated Parts Storage Systems

Centralize parts, tools, and spares. Reduce walking and search time. Keep production moving.

Why Traditional Parts Storage Breaks Down

-

Parts spread across shelves, cabinets, and cages

-

Excess walking and time spent searching

-

Overstocking “just in case” to avoid downtime

-

Poor visibility into spare parts inventory

-

Line stoppages waiting on critical components

What an Automated Parts Storage System Does

An automated parts storage system centralizes inventory vertically and delivers parts directly to the operator. Instead of walking aisles and searching bins, teams retrieve exactly what they need, when they need it—while maintaining visibility and control over inventory.

How Automated Parts Storage Works

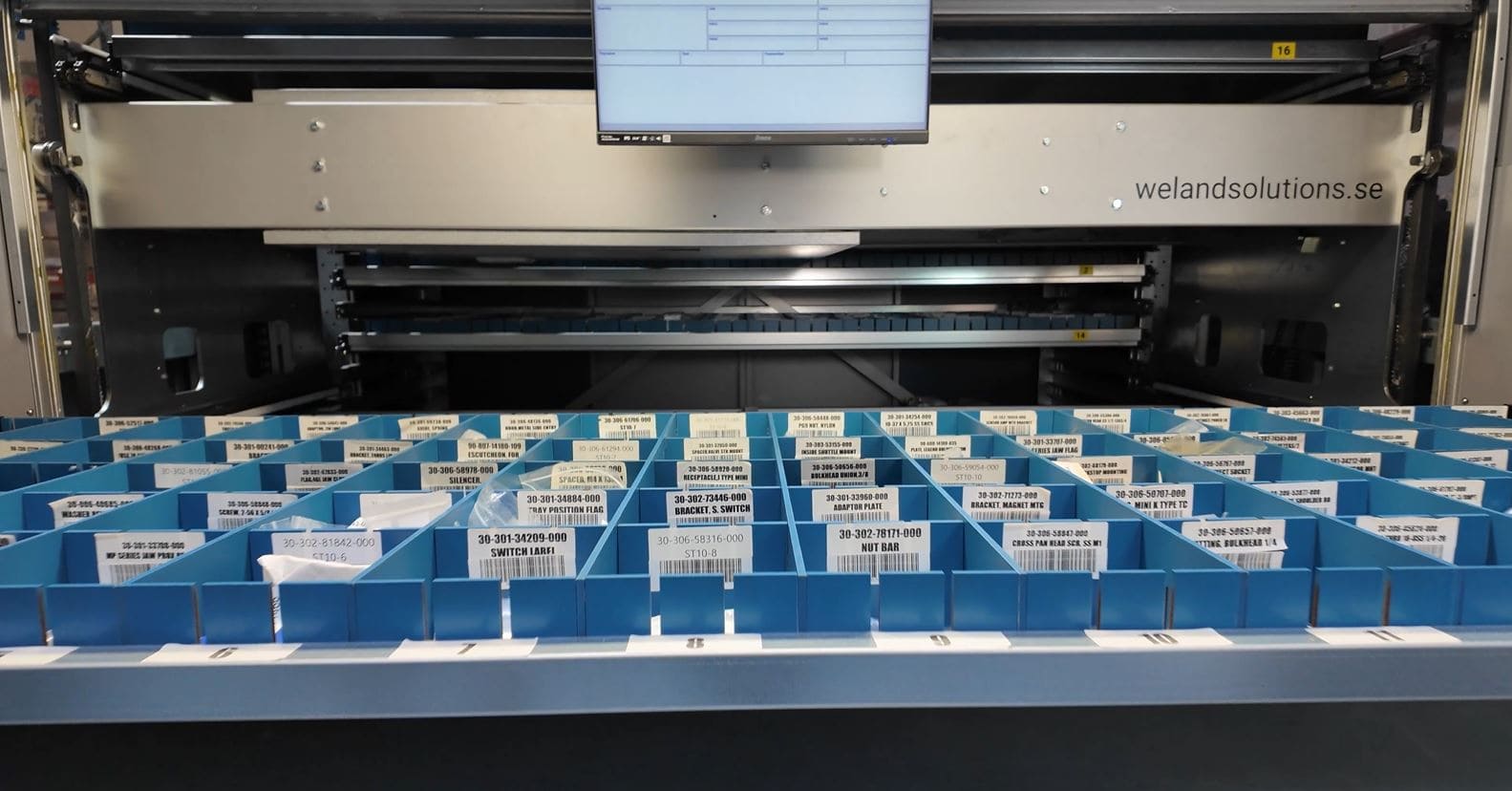

- Parts are stored in high-density trays or carriers

- Inventory locations are managed by software

- The system delivers the correct tray to the operator

- Picks are completed quickly and consistently

- Software-managed inventory ensures parts stay organized, traceable, and available when needed.

Technologies Used for Parts Storage

Vertical Lift Modules (VLMs)

High-density vertical storage for parts in minimal floor space.

Vertical Carousels

Continuous rotation for fast access when ceiling height is limited.

Horizontal Carousels

High-velocity parts picking across multiple SKUs.

Heavy-Duty Vertical Storage (PC3)

Organized storage for large or heavy parts.

Inventory & Control Software

Manages locations, access, and guided picking.

Benefits of Automated Parts Storage

- Faster access to maintenance and production parts

- Reduced walking and search time

- Better spare parts visibility and control

- More floor space for production and assembly

- Improved accuracy without relying on tribal knowledge

Proven in Real Manufacturing Environments

- 500+ bin locations eliminated

- Floor space recovered for production

- Cleaner, more organized parts access