Store More Inventory Without Using More Floor Space

Vertical Lift Modules (VLMs): The Complete Guide

Introduction: Why More Facilities Are Turning to Automated Storage

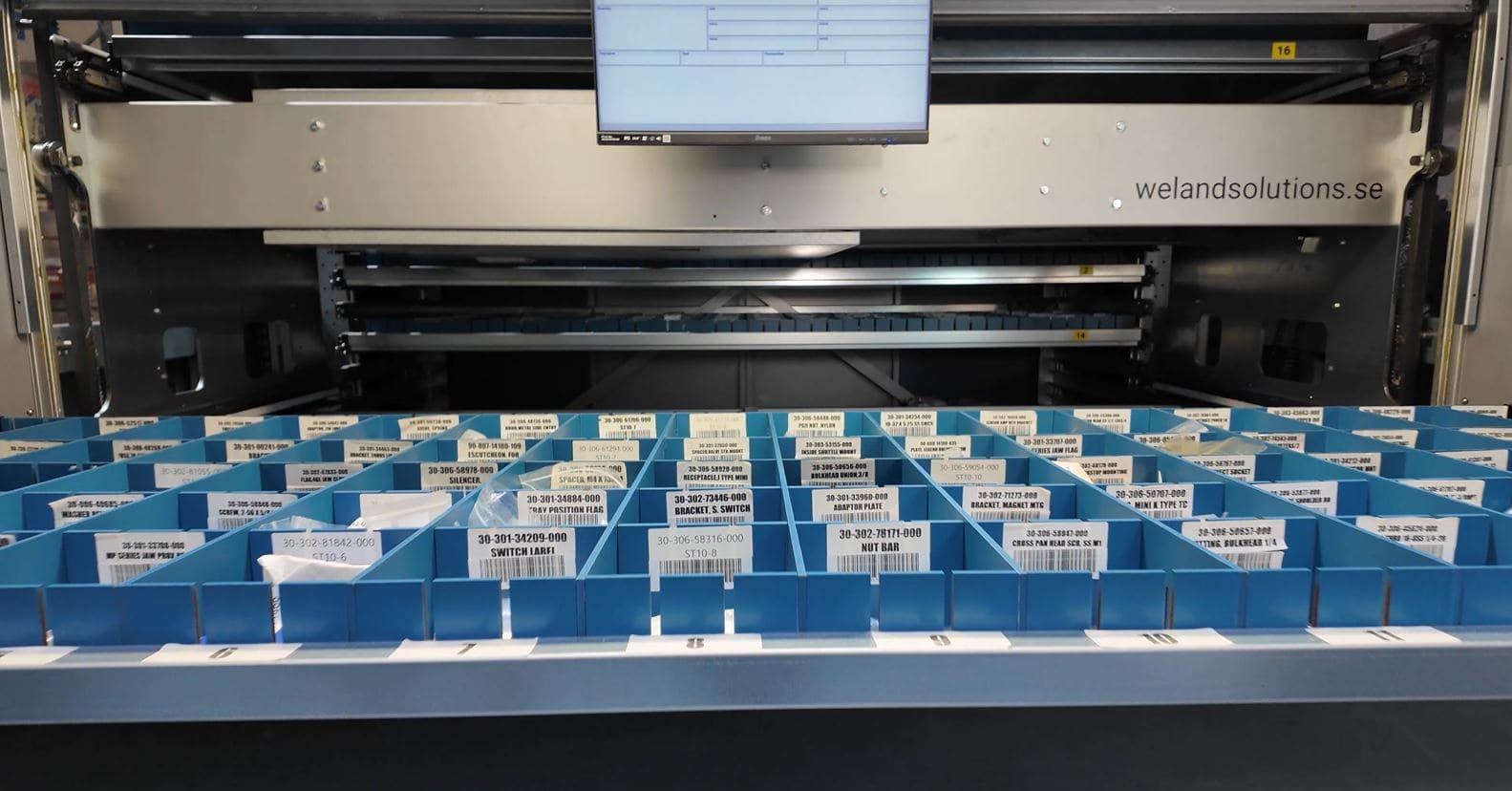

A Vertical Lift Module (VLM) is an automated, goods-to-person storage system that uses vertical space to store and retrieve inventory efficiently, accurately, and securely.

-

Recover up to 80–85% of floor space

-

Improve picking accuracy and throughput

-

Centralize and control inventory access

Every inch of warehouse and production space counts. Yet across manufacturing, maintenance, and distribution environments, as much as 60–70% of floor area is consumed by static shelving and aisles. Traditional storage not only limits capacity—it also introduces inefficiencies that ripple across the entire operation: longer retrieval times, ergonomic strain, and higher error rates.

That’s where Vertical Lift Modules (VLMs) come in.

A VLM is an enclosed, automated storage and retrieval system that uses the full height of your facility to deliver items directly to the operator at an ergonomic access window. By storing items vertically and bringing them to the user automatically, VLMs eliminate wasted travel time, maximize cubic storage density, and dramatically improve accuracy and throughput.

At White Systems, we’ve been designing, engineering, and supporting VLM technology for decades. Our Compact Lift, Compact Twin, and Compact Double models are trusted across industries—from manufacturing and aerospace to hospitals, labs, and MRO environments—because they combine reliability, flexibility, and proven ROI.

1. What Is a Vertical Lift Module (VLM)?

A Vertical Lift Module (VLM) is a fully enclosed automated storage system designed to maximize vertical space and deliver items directly to the operator. Inside the VLM, two columns of trays are arranged on either side of a central extractor. When an operator or connected software requests an item, the extractor automatically retrieves the correct tray and presents it at an ergonomic access opening.

This goods-to-person workflow eliminates walking, searching, and climbing, allowing operators to pick faster and more accurately while using a fraction of the floor space required by traditional shelving.

Core Technical Characteristics (Typical Ranges)

-

Tray width: up to 3,000 mm (118 in)

-

Tray depth: 820–860 mm (32–34 in)

-

Load per tray: up to 1,000 lbs (450 kg)

-

Machine height: 8–46 ft (customizable)

-

Positioning accuracy: ±1 mm

-

Cycle time: ~20–30 seconds per retrieval

Every White Systems VLM features automatic height sensing, dynamic storage allocation, and industrial-grade drive technology for smooth, consistent operation across demanding workflows.

2. How Does a Vertical Lift Module (VLM) Work?

A Vertical Lift Module operates on a simple but highly efficient concept: store inventory vertically and bring the required tray directly to the operator. The VLM’s internal extractor moves up and down between two columns of trays, automatically locating and retrieving the correct tray based on the operator’s request or a connected software command.

1. Dual Columns of Trays

Inventory is stored in two vertical columns—one on the left and one on the right. Each tray holds items based on weight, height, frequency of access, and SKU groupings. The system automatically chooses the optimal tray location to maximize density and balance the load.

2. Central Extractor

The extractor is the core of the system. It travels vertically between the tray columns, lifts or deposits trays, and delivers them to the access opening. Precise movement ensures accurate positioning and smooth operation even at high load capacities.

3. Automatic Height Sensing

As items are placed on a tray, the VLM measures their height. The system uses this information to determine where each tray should be stored, ensuring no vertical space is wasted. By using one-inch storage increments, the VLM continuously maximizes density without operator input.

4. Dynamic Storage Allocation

Unlike static shelving, trays in a VLM do not return to a fixed location. Instead, the system automatically assigns the most efficient storage position based on space availability and usage patterns. Frequently accessed trays can be stored closer to the access opening to speed up retrieval.

5. Goods-to-Person Access Opening

When a tray is requested, the extractor brings it directly to an ergonomic height at the access opening. Operators pick or replenish items without bending, reaching, or walking—reducing fatigue and improving accuracy.

6. Safety & System Controls

Every VLM includes a suite of built-in safety features, which typically include:

-

Light curtains to prevent operation while hands are inside

-

Door interlocks

-

Emergency stop buttons

-

Overload protection

-

Controlled motion profiles for smooth acceleration and braking

System controls manage tray locations, access permissions, operational modes, and integration with higher-level inventory systems when required.

3. Types of Vertical Lift Modules

White Systems manufactures several Vertical Lift Module configurations to support different capacity requirements, throughput needs, and inventory profiles. While all VLMs operate on the same goods-to-person principle, each model is engineered for specific workflows.

Each model can integrate with inventory management software and automation equipment to create a complete automated storage and retrieval solution (AS/RS) tailored to your facility.

4. Quantifiable Performance Advantages

When engineered correctly, a VLM transforms both storage density and operational efficiency.

For operations or facilities leaders, those numbers translate directly to lower operating costs per SKU and a 12–18-month ROI in most installations.

5. Design and Sizing Considerations

Selecting the right VLM starts with a clear understanding of your inventory profile and workflow.

Key design factors:

-

Ceiling Height: Determines maximum unit height and number of trays.

-

Item Dimensions & Weight: Dictate tray type, spacing, and payload.

-

Access Frequency: Drives the choice between single or twin extractor.

-

Integration Needs: WMS/ERP connectivity, barcode systems, or robotics.

-

Environmental Conditions: Cleanroom, temperature, or ESD requirements.

White Systems engineers work directly with your operations team to model layout, calculate space savings, and simulate throughput before installation.

6. Comparison: VLM vs. Other Storage Systems

A well-implemented VLM outperforms traditional shelving and carousels for dense, secure, and ergonomic storage.

7. Integration and Maintenance

Modern VLMs are designed to integrate seamlessly with existing IT and operational infrastructure.

Software Integration

-

Connects with ERP, WMS, and MES systems

-

Supports barcode, RFID, or badge-based user access

-

Generates pick lists, replenishment tasks, and real-time inventory reports

-

Interfaces with our software platform for centralized control and analytics

Maintenance & Reliability

White Systems provides nationwide service coverage with U.S.-based technicians.

-

Preventive maintenance visits (typically twice per year)

-

Remote diagnostics and troubleshooting

-

Guaranteed response times for contract customers

-

Availability of OEM parts and expert upgrades

Because each Compact VLM is built with heavy-duty industrial components and redundant safety systems, average uptime exceeds 99.5% across our installed base.

8. Applications Across Industries

VLMs are adaptable to virtually any environment requiring secure, high-density storage.

Because every unit is modular and customizable, White Systems can design a VLM solution around your unique parts profile, workflow, and compliance requirements.

9. Real-World Results

Case Example: Mardskog & Lindkvist — Wine and Spirits Distribution

A European food and beverage wholesaler installed three Compact Twin VLMs to replace traditional shelving for wine and spirits distribution.

Results:

-

78% reduction in floor space

-

4.5× increase in SKU capacity

-

Significantly faster order fulfillment

-

Ergonomic improvements and simplified training

Case Example: U.S. Manufacturer — Aerospace Components

A major aerospace supplier replaced 12 aisles of shelving with three Compact Lifts.

Results:

-

4× faster kitting

-

99.9% accuracy

-

ROI achieved in 14 months

These results are typical when VLMs are applied to high-mix, medium-volume storage operations with strict accuracy and traceability requirements.

10. The Future of VLM Technology

Case Example: Mardskog & Lindkvist — Wine and Spirits Distribution

A European food and beverage wholesaler installed three Compact Twin VLMs to replace traditional shelving for wine and spirits distribution.

Results:

-

78% reduction in floor space

-

4.5× increase in SKU capacity

-

Significantly faster order fulfillment

-

Ergonomic improvements and simplified training

Case Example: U.S. Manufacturer — Aerospace Components

A major aerospace supplier replaced 12 aisles of shelving with three Compact Lifts.

Results:

-

4× faster kitting

-

99.9% accuracy

-

ROI achieved in 14 months

These results are typical when VLMs are applied to high-mix, medium-volume storage operations with strict accuracy and traceability requirements.

11. Key Takeaways

-

Maximize Space: Save up to 85% of floor area and reclaim valuable square footage.

-

Improve Accuracy and Speed: Achieve 99.9% accuracy and up to 3× faster picking.

-

Enhance Safety: Reduce operator strain with ergonomic access heights.

-

Integrate Seamlessly: Connect to your ERP/WMS and maintain full visibility.

-

Trust Proven Engineering: White Systems provides robust machines backed by U.S.-based service and decades of experience.

12. Frequently Asked Questions

-

Q: How much does a Vertical Lift Module cost?

Costs vary depending on height, configuration, and options.Q: Can VLMs handle heavy or oversized items?

Yes. The Compact Double is built for large, heavy, or bulky items and supports up to 2,200 lbs per tray.Q: How tall can a VLM be?

White Systems VLMs are custom-engineered up to 46 feet tall to take advantage of building height and maximize capacity.Q: What maintenance is required?

Preventive maintenance is minimal—typically twice per year—to inspect drive systems, sensors, and tray alignment.Q: Do VLMs integrate with existing software?

Yes. Our systems integrate with leading ERP and WMS platforms, and our control software provides a single interface for all White Systems automation.

Conclusion: The Smarter Way to Store

Vertical Lift Modules are the future of industrial and commercial storage—delivering measurable improvements in space utilization, accuracy, and labor efficiency. With robust engineering, integrated software, and nationwide support, White Systems VLMs are designed to perform reliably for decades.

If you’re ready to explore what a VLM can do for your operation:

Take it With You

Download the Guide in pdf format.